By Reg Nicoson

Basics

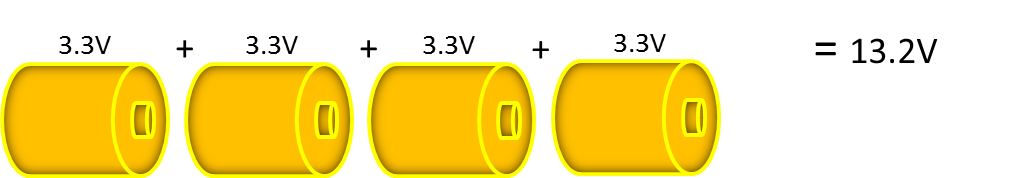

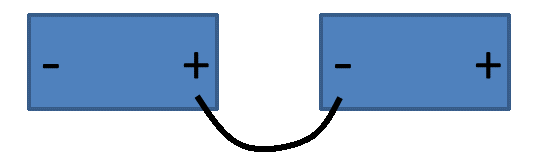

Battery packs are designed by connecting multiple cells in series; each cell adds its voltage to the battery’s terminal voltage. Figure 1 below shows a typical EarthX 13.2V LiFePO4 starter battery cell configuration.

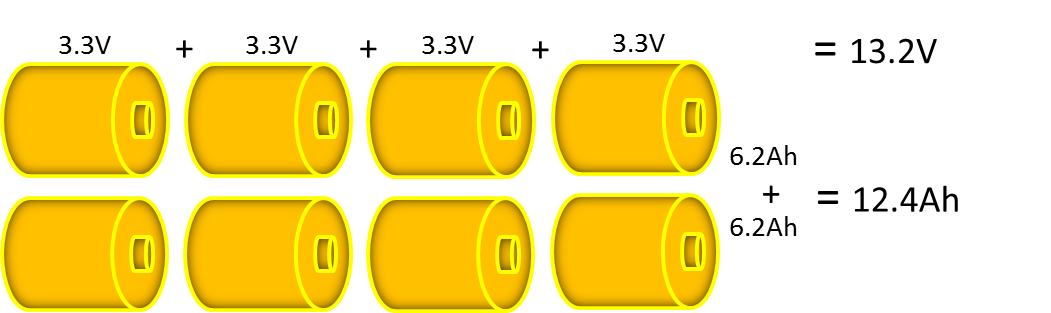

Batteries may consist of a combination of series and parallel connections. Cells in parallel increased current handling; each cell adds to the ampere-hour (Ah) total of the battery The EarthX ETX680 is an example of a series and parallel configuration. The ETX680 configuration, 13.2V / 12.4Ah, is shown in Figure 2.

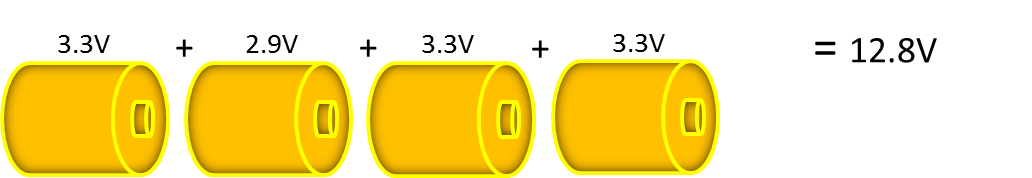

A weaker cell in series connected cells would cause an imbalance. This is especially critical in a series configuration because a battery is only as strong as the weakest cell (analogous to the weak link in the chain). A weak cell may not fail immediately but may be drained (voltage dropping below a safe level, 2.8V per cell) more quickly than the strong ones when discharging. On charge, the weak cell may fill up before the healthy ones and be over-charged (voltage exceeding 3.9V per cell). Unlike the weak link in a chain analogy, a weak cell causes stress on the other healthy cells in a battery. Cells in multi-packs must be matched, especially when exposed to high charge and discharge currents. Figure 3 below shows an example of a battery with a weak cell.

Battery Management System (BMS) Cell Protection

A BMS continuously monitors each cell’s voltage. If the voltage of a cell exceeds the others, the BMS circuits will work to reduce that cell’s charge level. This ensures that the charge level of all the cells remains equal, even with the high discharge (> 100Amps) and charge current (>10Amps).

A cell can be permanently damaged if over-charged (over-voltage) or over-discharged (drained) just one time. The BMS has circuitry to block charging if the voltage exceeds 15.5 volts (or if any cell’s voltage exceeds 3.9V). The BMS also disconnects the battery from the load if it is drained to less than 5% remaining charge (an over-discharge condition). An over-discharged battery typically has a voltage less than 11.5V (< 2.8V per cell).

Multiple Batteries in Series and or Parallel (each battery with its own BMS)

EarthX batteries are approved for use in applications with up to two batteries in parallel, with no additional external electronics. The restriction to two batteries allows for normal variations in one battery without adversely affecting the other battery. For applications with more than two batteries in parallel, please contact EarthX tech support.

EarthX batteries are NOT approved for series operation without EarthX’s engineers design approval. This restriction is due to the fact that impedance, capacity, or self-discharge rates vary between cells and between batteries. EarthX offers many 26.4 volt batteries. It is always preferred to use a single 26.4 volt battery versus two 13.2 volt batteries in series, for the single battery can internally monitor each of the 8 cells in series and ensure the charge level of all cells are balanced.

The wire and connectors used to make the series/parallel array of batteries shall be sized for the currents expected.

Do not connect EarthX batteries with other chemistry batteries.

It is important to use the same battery model with equal voltage and capacity (Ah) and never to mix batteries of a different age.

Please contact EarthX for additional information or application support.

Parallel Operation

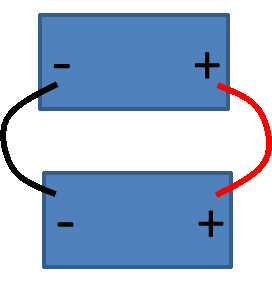

Like individual cells, you can combine batteries together in parallel to achieve higher energy/power (amp-hours, amps). Up to two batteries can be put in parallel. To combine batteries in parallel, connect positive to positive and negative to negative as shown in Figure 4 right.

It is important to use the same battery model with equal voltage and never to mix batteries of a different age.

When connecting two batteries, it is important to make sure the charge levels are similar (voltages are within 0.3 volt) before connection. If there is a large difference in charge level, high current can flow between the batteries.

In situations where the batteries are automatically connected/disconnected there must be external equipment to limit the current to less than the batteries maximum charge current specification and/or interconnecting wire ampacity specification.

Series Operation

Unlike parallel operation, series operation or series/parallel operation requires thoughtful engineering and maintenance to make the system function properly. Contact engineering for design approval. It is important to use the same battery model with equal voltage and capacity (Ah) and never to mix batteries of a different age. Both batteries in a series configuration must have the EXACT same load, meaning you cannot connect a load to just one battery in the series. If you charge one battery you must charge the other to an equal charge level. If you replace one battery, you must replace the other battery. See the example below for series wiring (Figure 5).

Series / Parallel Operation

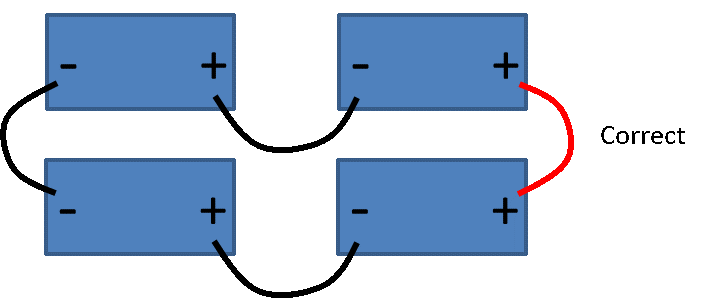

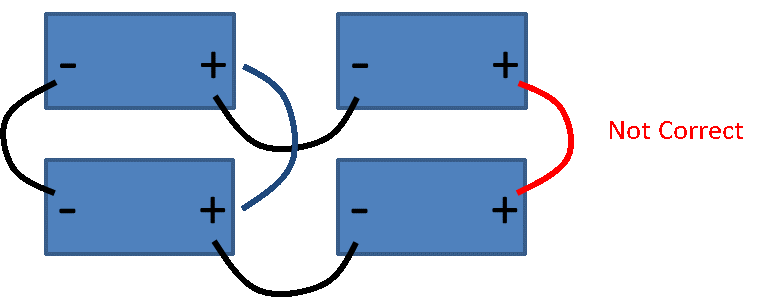

Below is the approved series and parallel configuration (Figure 6). The batteries are wired as two separate series battery paths, meaning there is no cross ties between the centers of the two separate paths. Figure 7 shows an incorrect connection with a cross tie between the centers of the two separate series paths.

Maximum Safe Operating Limits

Based on extensive testing and knowledge of the cells and BMS design, our battery’s nameplate ratings are de-rated when used in parallel and or series configurations. For example, the normal maximum charging voltage for a single battery is 14.6V, but when two batteries are put in series the combined normal maximum charging voltage is reduced to 28.8V. When two batteries are put in parallel the continuous discharge amp rating and charge amp rating is typically reduced to 90% of the two batteries’ combined rating.

Our EarthX batteries have the capability of extremely high discharge rates and charge rates. However, when our batteries are connected in series and or parallel we recommend you don’t exceed the values shown in Table 1 below. Please contact us for applications using battery models not shown in this document.

| Model | # in Parallel | # in Series | Max Continuous Discharge Amps | Max Charge Amps | Max Charge Volts |

| ETX18 | Instead of two ETX18 in parallel use one ETX36 | ||||

| ETX18 or ETX24 | Instead of two in series use one ETX400-24 | ||||

| ETX680/ETX680C | Instead of two ETX680C in parallel use one ETX1200 | ||||

| ETX680/ETX680C | Instead of two ETX680C in series use one ETX680-24-VNT or ETX900-24 | ||||

| ETX900 | Instead of two ETX900 in parallel use one ETX1600 | ||||

| ETX900 | Instead of two ETX900 in series use one ETX900-24 | ||||

| ETX1200 | Instead of two ETX1200 in parallel use one ETX1600 | ||||

| ETX1200 | Instead of two ETX1200 in series use two ETX680-24-VNT or ETX900-24 in parallel | ||||

| ETX1600 | Instead of two ETX1600 in series use one ETX1200-24 | ||||

| ETX900-24 | 2 | 1 | 270A | 144A | 28.8V |

Series / Parallel Operation and Fault Indication

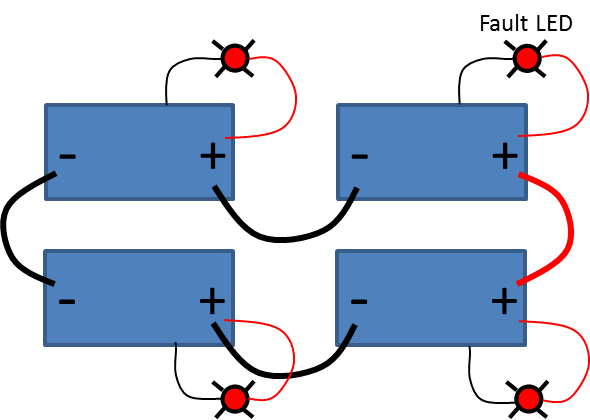

Each EarthX battery requires its own remote fault indication LED. The 12V LED is connected across the battery’s positive terminal and the remote fault indicator wire (pigtail wire out the side of the battery), see Figure 8 below. Connecting the remote fault indicator to an EFIS is not an option in any series configuration (12V LED light is the only option).

Series / Parallel Operation Charging (maintenance)

With an approved engineering design, when using two 13.2 volt batteries in series, it is most important to keep the two batteries matched. If charging is needed, both batteries must be charged to an equal level. If a battery needs to be replaced, both batteries must be replaced. Both batteries must have matching capacity, and charge level always.

References

Source1 – EarthX Lithium Battery User’s Manual